Goodman Gas Furnace: GMS9/GCS9

Re: Flashing Code 4

(Assuming original control board)

Code 4 = Limit Circuit Open

If the Limit Circuit opens, the burners will be de-energized and the air circulation and vent blower will be turned on until the Limit Circuit closes. The diagnostic light code for this is four short flashes followed by a pause.

► The diagnostic code will go away once the Limit Circuit closes (not a Hard Lockout).

| Qty |

Possible Causes: |

| 1 |

Bad Blower Motor / Capacitor |

|

Dirty Air Filter |

|

Bad Control Board |

|

Clogged Evaporator Coil |

|

Under-sized Ductwork |

|

High Gas Pressure |

|

Bad Limit |

|

Blower Speed too Low |

CHECKOUT:

1. Check Blower Operation

- When the furnace is Flashing Code 4, the indoor blower and inducer motor should be running.

- Ensure that the blower motor is operating and airflow is coming from the registers.

2. Check Control Board

- If the furnace is still in a Code 4 lockout, the blower should be operating, so move on to the Voltage Check.

- If the Code 4 goes away, activate either a call for Heat W or Fan G to get the blower to Power On.

- Voltage Check

- Check for 120V between CIR-N and HEAT.

- Power Present + Blower Operates → Step 3. Check Limits

- Power Present + No Blower Operation = Bad Blower Motor or Capacitor

- No Power ⇒ Check for power between CIR-N and COOL.

- Still No Power = Bad Control Board

3. Check Limits

- There are (2) limits in the Limit Circuit that will generate a Code 4: (1) Auto-Reset Limit in the furnace heat exchanger and (1) Manual-Reset Limit (In the Blower Deck on Upflow, or On the Blower Housing on Counterflow).

- Check the Limit Circuit

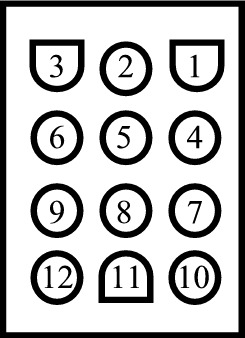

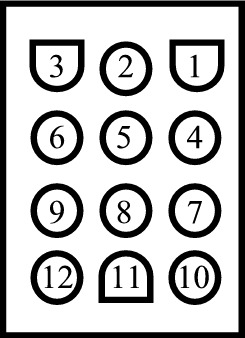

- Check for 24V between "C" and Pin #1 (Pink) of the 12-pin plug on the circuit board.

- Check for 24V between "C" and Pin #7 (Blue) of the 12-pin plug on the circuit board.

- Power on Both Pins = Limit Circuit Closed

- Limit Circuit Closed + Code 4 = Bad Control Board

- Power on One Pin Only = Limit Circuit Open

- Check for 24V between "C" and both sides of each limit to determine which is Open.

4. Check Temperature Rise

- Start the furnace with a call for heat.

- Check and record the return air temperature near the furnace (at the filter if possible) with the blower on.

- Check the supply air temperature (in a straight duct run near the furnace) as the furnace operates.

- Compare the actual temperature rise to the rated temperature rise on the furnace nameplate. (typically 40 - 70 deg.)

5. Check Air Filter

- Remove air filter and recheck temperature rise.

6. Check Gas Pressure

- De-energize the call for heat and allow the furnace to cool.

- Turn off power to the furnace and close the gas safety shut-off.

- Hook-up a gas pressure gauge to the manifold (leaving) test port on the gas valve.

- Open the gas safety shut-off valve and re-apply furnace power.

- Activate a call for heat and monitor the manifold gas pressure when the gas valve opens.

- Natural Gas = 2.5" w.c. minimum to 3.5" w.c. maximum

- LP Gas = 9" w.c. minimum to 11" w.c. maximum

7. Check Blower Speed

- Check the blower motor speed wire attached to the "Heat" output of the control board.

- Red = Low

- Yellow = Med Low

- Blue = Med Hi

- Black = Hi

- If possible, increase the Heat blower speed and Re-Check Temperature Rise

8. Check Duct Static Pressure

- Check the return static pressure (in the blower door if possible).

- Check the supply static pressure (between the furnace and evaporator coil if possible).

- High Duct Static = Above 0.5" w.c.

- High Return Static + Low Supply Static = Restricted Return Ductwork

- Low Return Static + High Supply Static = Clogged Coil or Restricted Supply Ductwork

- Compare static on both sides of evaporator coil.

- High Static Entering Coil + Low Static Leaving Coil = Clogged Coil

- Low Return Static + Low Supply Static = Dirty Blower Wheel or Dirty Recoup Coil