Carrier Gas Furnaces: 395CAV

Re: Flashing Code 33 / Fault Code 33

Flash Sequence = 3 Short Flashes + 3 Long Flashes (- - - , — — —)

Code 33 = Open Limit or Roll-Out

The Primary Limit is wired in series with other limits, including up to two Roll-out Switches or a Fusible-Link roll-out switch.

Therefore, a Fault Code 33 can be caused by one of the following:

- Primary Limit Switch Open.

- Rollout Switch Open

► If the limit circuit stays open for more than 3 minutes, the code changes to Code 13.

| Qty |

Possible Causes: |

|

Dirty Filter |

| 1 |

Clogged Evaporator Coil |

|

Restricted Ductwork |

|

Bad Heat Exchanger |

|

Bad Limit Switch |

|

Excessive Gas Pressure |

|

Bad Control Board |

CHECKOUT:

1. Check Furnace Operation

- Start the furnace with a call for heat.

- If there is power on "W" at start-up, the furnace will run the blower for 90 seconds and flash a Code 12.

- Code 33 Immediately or Before Burners → Step 6. Check Limit Circuit

- Blower motor should start within 30 - 60 seconds after ignition.

2. Check Blower Motor

- Restart an ignition sequence and allow burners to ignite.

- Check for 115VAC between "Neutral" and "Heat" on the control board.

- No Power = Bad Control Board

- Power + No Blower = Bad Motor or Capacitor

3. Check Temperature Rise

- Check the temperature rise as the furnace operates.

- Compare the actual temperature rise to the rated temperature rise on the furnace nameplate. (typically 40 - 70 deg.)

- Temperature rise below maximum + Limit Trips = Bad Limit

- Temperature rise at or above maximum ⇒ Remove the air filter and recheck the temperature rise.

4. Check Gas Pressure

- Monitor the manifold gas pressure when gas valve opens.

- Natural Gas = 2.5" w.c. minimum to 3.5" w.c. maximum

- LP Gas = 9" w.c. minimum to 11" w.c. maximum

5. Check Duct Static Pressure

- Check the return static pressure (in the blower door if possible).

- Check the supply static pressure (between the furnace and evaporator coil if possible).

- High Duct Static = Above 0.5" w.c.

- High Return Static + Low Supply Static = Restricted Return Ductwork

- Low Return Static + High Supply Static = Clogged Coil or Restricted Supply Ductwork

- Compare static on both sides of evaporator coil.

- High Static Entering Coil + Low Static Leaving Coil = Clogged Coil

6. Check Limit Circuit

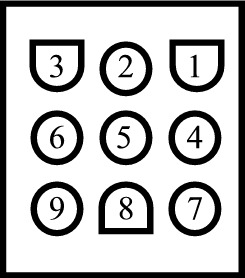

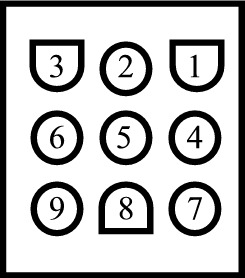

- Check for 24VAC between "24V Com" and the RED wire on Pin #1 of the 9-pin plug.

- Check for 24VAC between "24V Com" and the RED wire on Pin #7 of the 9-pin plug.

- Power on Pin #1 + Power on Pin #7 + Code 33 = Bad Control Board

- Power on Pin #1 + No power on Pin #7 = Open Circuit --> Check Each Switch

- Primary Limit

- Check for 24VAC between "24V Com" and both sides of the Primary Limit Switch.

- Power on Both Sides = Limit OK

- Power on One Side Only = Open Switch

- Heat Exchanger Cool = Bad Limit

- Heat Exchanger Hot ⇒ Allow time to cool and re-check.

- Rollout Switch

- Check for 24VAC between "24V Com" and both sides of the Rollout Switch(es).

- Power on Both Sides = Limit OK

- Power on One Side Only = Open Switch ⇒ Reset switch and Check Heat Exchanger!