York 90% Gas Furnace: P3UR

Re: Flashing Code 3

Code 3 = Furnace Pressure Switch failed to close on a call for heat.

| Qty |

Possible Causes: |

| 2 |

Bad Inducer Motor |

| 1 |

Bad Pressure Switch |

| 1 |

Clogged / Frozen Drain |

| 1 |

Pressure Hose Problem |

| 2 |

Item Stuck in Inducer Motor |

|

Water in the vent (improper slope) |

|

Water in inducer (clogged drain) |

| 1 |

Vent/Intake Problem |

|

Bad Ignition Control |

CHECKOUT:

1. Check Control Board

- Start the furnace with a call for heat.

- Ensure that 24VAC is present between "W" and "C".

- The Inducer motor should start within 15 seconds.

- Inducer Motor Starts → Step 2. Check Inducer

- Inducer Motor Does Not Start + Code 3 ⇒ Check for 115V power to inducer.

2. Check Inducer

- Observe and listen to the inducer motor.

- Inducer motor starts and runs normally → Step 3. Check Pressure Switch

- Inducer motor does not try to run ⇒ Check the temperature of the motor. If it is hot and not running, it is probably off on its internal overload and may need to cool.

- Inducer motor hums but does not start:

- Bad Inducer Motor or Capacitor

- Item in Inducer ⇒ Remove inducer & check

- Sound of Water "slurshing" = Water in Inducer ⇒ Remove Inducer, pour out water, re-install inducer → Step 4. Check Condensate Drainage

- Listen for sounds of water in the vent piping.

- If water is gurgling in the vent, look for low spots that will hold water.

- The vent piping must have a constant slope back toward the furnace.

3. Check Pressure Switch

- Some models have 2 pressure switches wired in series - one for the vent and one for the collector box drain.

- Make sure there are no sags in the pressure switch hoses that could hold water.

- Switch Contacts

- With the inducer motor running, check for 24VAC between each side of the pressure switch(es) and "C"

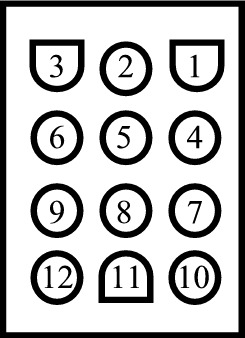

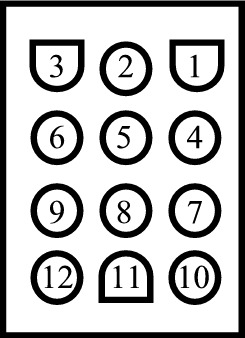

- Alternative Method - Check for 24VAC at the molex plug between Pin# 7 - White and "C" and Pin #10 - Blue and "C".

- Power on One Side Only = Switch Open

- Power on Both Sides = Switch Closed

- Switch Closed + Code 3 = Bad Control Board

- Switch Pressure

- Inspect the pressure switch tubing for a:

- Loose hose

- Dry-rotted, cracked hose

- Clogged hose

- Use a pressure meter to check the pressure at the 1LP vent switch.

- ► Must check positive & negative pressure together (differential pressure).

- Use a pressure meter to check the pressure at the 2LP drain switch (if present).

- Compare actual pressure to the pressure rating on the switch.

- Vent Switch

- Pressure Near or Below the Switch Rating (0.90" w.c.) = Vent/Intake Issue ⇒ Check the negative pressure at the inducer and burner box individually.

- Inducer Negative Pressure Low = Inducer Problem ⇒ Remove inducer & check for obstructions or damaged wheel.

- Burner Box Negative Pressure High = Intake Problem ⇒ Remove the burner box cover to see if pressure improves.

- Pressure Well Above Rating + Open Switch = Bad Switch or Water in Switch

- Drain Switch (if present)

- Pressure Near or Below the Switch Rating = Drainage Issue ⇒ Remove the pressure hose from the collector box to see if water drains out.

4. Check Condensate Drainage

- There are three drains that tie-in to the factory drain trap.

- Vent Outlet

- Inducer Motor

- Collector Box

- Remove each drain hose individually.

- Water running out of Drain = Clogged Drainage

- Remove the drain trap and flush-out at a sink.

- Check the main drain line.

- In extreme cold conditions be cautious of Frozen Drains.