|

Article ID: 346

Last updated: 9 Nov, 2022

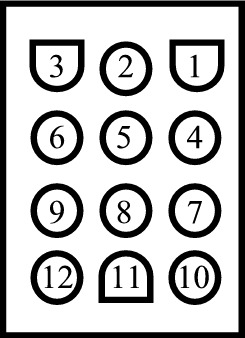

York Gas Furnace: PHU Re: Flashing Code 4 (Assuming original control board) CODE 4 = High Limit or Spill Limit Open If the limit control opens, the burners will be de-energized and the air circulation and vent blower will be turned on until the limit closes. The diagnostic light code for this is four short flashes followed by a pause. ► The diagnostic code will go away once the limit switch closes. ► A Code 4 will rarely be the reason for a "No Heat" call (unless the Manual-Reset Spill Limit is tripped, the Primary Limit is bad, or the Blower Motor has failed).

CHECKOUT: 1. Check Limit Circuit

3. Check Blower Motor/Capacitor

This article was:

Helpful |

Not helpful

Report an issue

Article ID: 346

Last updated: 9 Nov, 2022

Revision: 10

Access:

Public

Views: 205

Comments: 0

|

Powered by KBPublisher (Knowledge base software)