Trane Gas Furnace: TUD/TDD

Re: Flashing Code 4

Code 4 = Limit switch open

There are 4 limits wired in series: a Reversed Flow Limit in the blower compartment (auto-reset), two Roll-Out Limits (manual-reset), and a Primary Limit (auto-reset).

| Qty |

Possible Causes: |

|

Bad Blower Motor/Capacitor |

|

Bad Reversed Flow Limit |

|

Bad Heat Exchanger |

|

Bad Roll-Out Limit |

|

Furnace Over-Heating |

|

Bad Primary Limit |

CHECKOUT:

1. Check the Limit Circuit

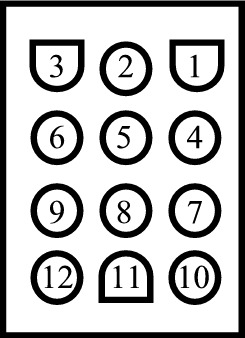

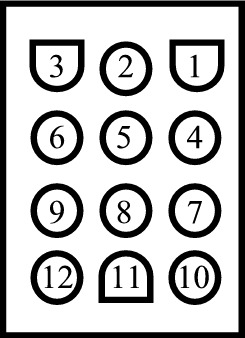

- At the control board 12-pin plug, check for 24VAC between HLO Pin #1 (Yel) to "C".

- At the control board 12-pin plug, check for 24VAC between HLI Pin #7 (Yel) to "C".

- No Power on Either Pin = No Control Power or Bad Control Board

- Power on HLO Pin #1 only = Limit Circuit Open → Step 2. Check Limits

- Power at both Pins #1 & #7 = Limit Circuit Closed

- Limit Circuit Closed + Code 4 = Bad Control Board

2. Check Limits

- Reversed Flow Limit

- Check for 24VAC at both sides of the limit (located on the blower housing).

- Roll-Out Limits

- Check for 24VAC at both sides of each roll-out limit (located above the burners).

- Primary Limit

- Check for 24VAC at both sides of the primary limit (located on the heat exchanger plate).

- Power on One Side Only = Limit Open → Step 5. Check Temperature Rise

3. Check Blower Motor

- If the limit circuit is open and there is a call for heat (24VAC on "W") the inducer motor and the blower motor should be running.

- Blower Operating + Open Reversed Flow Limit ⇒ Suspect a Bad Reversed Flow Limit

- Blower Motor Not Operating ⇒ Check for 120VAC going to the blower motor between control board "CIR-N" & "HEAT".

- Code 4 + No Power = Bad Control Board

- Power Present + No Blower Operation ⇒

- Turn off power to the furnace

- Check to see if the motor spins freely

- Check motor temperature (a hot motor may be off on internal overload)

- Check the blower motor capacitor

4. Check Burners/Heat Exchanger

- Reset the tripped roll-out limit by pressing the button in the center of the limit switch.

- Activate a call for heat (if not already calling).

- Code 4 should go away and an ignition sequence should start.

- Watch burners for proper ignition.

- Continue to watch burners when the blower motor starts.

- Roll-out or significant change in burners = Bad Heat Exchanger

5. Check Temperature Rise

- Start the furnace with a call for heat.

- Check and record the return air temperature near the furnace (at the filter if possible) with the blower on.

- Check the supply air temperature (in a straight duct run near the furnace) as the furnace operates.

- Compare the actual temperature rise to the rated temperature rise on the furnace nameplate. (typically 40 -70 deg.)

- Temperature Rise Below Maximum + Code 4 ⇒ Suspect Bad Primary Limit

- Temperature Rise Near or Above Maximum = Furnace Over-Heating ⇒

- Check Air Filter

- Check Gas Pressure

- Check Blower Speeds

- Check Recoup Coil

- Check Duct Static Pressure