Goodman Package Unit: GPG13

Re: Flashing Code 1 / Won't Ignite

Code 1 = 3 Failed Ignition Attempts

► A Manual-Reset Auxiliary Limit and Roll-Out Limit are wired in series with the gas valve and will cause a Fault Code 1.

| Qty |

Possible Causes: |

|

Dirty Flame Sensor |

|

Bad Control Board |

|

Tripped Auxiliary Limit |

|

Tripped Roll-Out Limit |

|

Bad Gas Valve |

| 2 |

Bad Spark Electrode or Spark Wire |

CHECKOUT:

1. Check Ignition Sequence

- If necessary, reset the furnace lockout by cycling high voltage or low voltage power.

- Initiate a call for heat from the thermostat and monitor the ignition sequence.

- The inducer motor should start with no difficulty.

- The pressure switch should close within a couple seconds of the inducer starting.

- The Sparker should begin sparking and the Gas Valve should open.

2. Check Control Board Output

- Re-start the furnace with a call for heat from the thermostat.

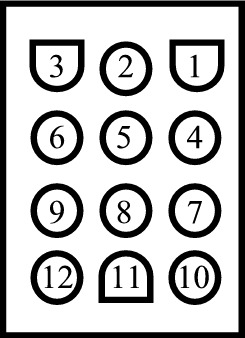

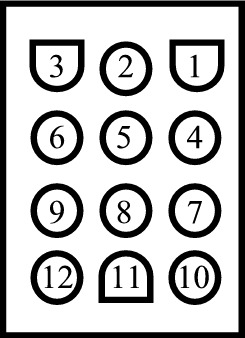

- At the point of ignition, check for 24VAC between Terminal 3 (Purple) of the molex plug on the control board and "Common".

- If the burners are running, wiggle the Purple wire at the molex plug to see if the gas valve drops-out (we've had several issues of a bad connection).

3. Check Gas Valve

- Re-start the furnace with a call for heat from the thermostat.

- At the point of ignition, check for 24VAC between (PUR) and (BL) at the gas valve.

- Power at Gas Valve + No Ignition → Step 4. Check Gas Pressure

- Power at Molex Plug + No Power at Gas Valve ⇒ Check for Tripped Auxiliary Limit or Tripped Roll-Out Limit

- Tripped Auxiliary Limit = Protection against blower failure

- Tripped Roll-Out Limit = Protection against a bad heat exchanger

4. Check Gas Pressure

- Inlet Gas Pressure

- Turn off power to the furnace and check the inlet gas pressure.

- Minimum Pressure = 5" w.c. for Nat. Gas, and 11" w.c. for Propane.

- No or Low Pressure = Bad Meter or Regulator

- Normal Pressure ⇒ Continue

- Re-apply power to the furnace and activate a call for heat.

- Make sure the inlet gas pressure stays above minimum when the gas valve energizes.

- Pressure Drops Below Minimum = Bad Meter/Regulator or Restricted Gas Line

- Normal Pressure ⇒ Check Manifold Gas Pressure

- Manifold Gas Pressure

- Activate a call for heat and monitor the manifold gas pressure during an ignition attempt.

- Normal Pressure = 2.5 - 3.5" w.c. for Nat. Gas, 9 - 11" w.c. for LP

- No Gas Pressure = Bad Gas Valve

- Low Gas Pressure ⇒ Increase Manifold Gas Pressure

- Normal Gas Pressure + No or Delayed Ignition = Clogged Burners ⇒ Remove burners and clean spreaders

5. Check the Sparker / Electrode

- With No Call for Heat, check the spark electrode wire from the control board to the electrode.

- Make sure the wire makes good contact at the control board.

- Look for any rubbed spots that may cause a short.

- Inspect the spark electrode.

- Check for damage.

- Look for any rust particles or other potential shorts.

- Check the Spark Generator:

- Remove the spark cable from the control board and attach a good jumper wire to the spark terminal.

- Turn the gas valve to the "Off" position.

- Activate a call for heat.

- Hold the open end of the jumper wire near a grounded piece of metal (be careful to not get shocked).

- Sparks ⇒ Suspect a Bad Spark Electrode or Spark Wire

- No Spark = Bad Control Board

6. Check Flame Sensor

- DO NOT clean the flame sensor before testing!

- On the multi-meter:

- Switch the test leads to "COM" and "mA".

- Set the meter on DC 200ù.

- Check the reading when the burners ignite.

- Minimum acceptable reading = 1 MicroAmp

- Low Reading ⇒ Clean Flame Sensor & Re-check

- Normal Reading (2 to 6 mA) + Shuts Off ⇒ Suspect a Bad Control Board

- MOVE SENSOR LEADS BACK TO "COM" and "V" BEFORE PROCEEDING!