Ameristar Package Unit: M4PG4

Re: Flashing Code 4

Code 4 = Main Limit switch or Aux Limit (not a Roll-Out Limit) has opened its normally closed contacts.

- The control will operate the supply air blower and inducer while the open limit condition exists.

► The manual-reset Aux Limit is located in the blower compartment.

► The automatic-reset Main Limit Switch is located in the main burner compartment.

| Main Limit Switch |

Aux Limit Switch |

| Qty |

Possible Causes: |

Qty |

Possible Causes: |

|

Dirty or Restrictive Air Filter |

1 |

Bad Blower Motor |

|

Clogged Evaporator Coil |

|

No Air Circulation |

|

High Duct Static |

|

Power Failure |

| 2 |

High Gas Pressure |

|

Bad Limit Switch |

| 1 |

Bad Limit |

|

|

| 1 |

Blower Speed too Low |

|

|

CHECKOUT:

1. Check Limits

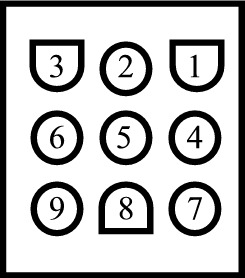

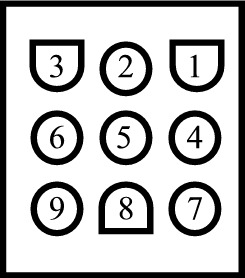

- At the 9-pin plug of the control board:

- Check for 24VAC between the Purple wire at Terminal 8 and "C".

- Check for 24VAC between the Red wire at Terminal 9 and "C".

- Power on Both Terminals = Limit Circuit OK → Step 2. Check Temperature Rise

- Power on One Terminal Only = Open Limit Circuit

- Check for 24VAC between each Red wire of the Main limit

- Check for 24VAC between each Red wire of the Aux limit

2. Check Temperature Rise

- 1st Stage Heat

- Un-hook the thermostat wire from W2 at the furnace.

- Start the furnace with a call for heat.

- Check the temperature rise across the furnace.

- Compare the actual temperature rise to the rated temperature rise on the furnace nameplate.

- Temperature Rise At or Above Maximum → Step 3. Check Air Filter

- Temperature Rise Below Maximum but Limit Trips ⇒ Suspect Bad Limit

- 2nd Stage Heat

- Reconnect the thermostat wire to W2 at the furnace.

- Place a temporary jumper between W1 & W2.

- Start the furnace with a call for heat.

- Check the temperature rise across the furnace.

- Compare the actual temperature rise to the rated temperature rise on the furnace nameplate. (typically 40 - 70 deg.)

- Temperature Rise At or Above Maximum → Step 3. Check Air Filter

- Temperature Rise Below Maximum but Limit Trips ⇒ Suspect Bad Limit

3. Check Air Filter

- Remove air filter and recheck temperature rise.

- Temperature rise drops into normal range = Clogged or Restrictive Air Filter

- Temperature rise still too high → Step 4. Check Gas Pressure

4. Check Gas Pressure

- De-energize the call for heat and allow the furnace to cool.

- Check the manifold gas pressure.

- 1st Stage Heat

- Natural Gas = 1.5 to 2" w.c.

- LP Gas = 6" to 8" w.c.

- 2nd Stage Heat

- Natural Gas = 2.5 to 3.5 " w.c.

- LP Gas = 9" to 11" w.c.

- Pressure Above Maximum ⇒ Adjust Gas Pressure & Re-check Temperature Rise

- Pressure Below Maximum + Still Over-Heating → Step 5. Check Blower Speed

5. Check Blower Motor & Blower Speed

- Check the Blower motor speed wire attached to the "Low" and "Single/Hi" outputs of the control board.

- Red = Low

- Yellow = Med Low

- Gray = Med

- Blue = Med Hi

- Black = Hi

- If possible, increase the Heat blower speed and Re-Check Temperature Rise

6. Check Duct Static Pressure

- Check the return static pressure (in the blower door if possible).

- Check the supply static pressure (between the furnace and evaporator coil if possible).

- High Duct Static = Above 0.5" w.c.

- High Return Static + Low Supply Static = Restricted Return Ductwork

- Low Return Static + High Supply Static = Clogged Coil or Restricted Supply Ductwork

- Compare static on both sides of evaporator coil.

- High Static Entering Coil + Low Static Leaving Coil = Clogged Coil