|

Article ID: 81

Last updated: 3 Feb, 2017

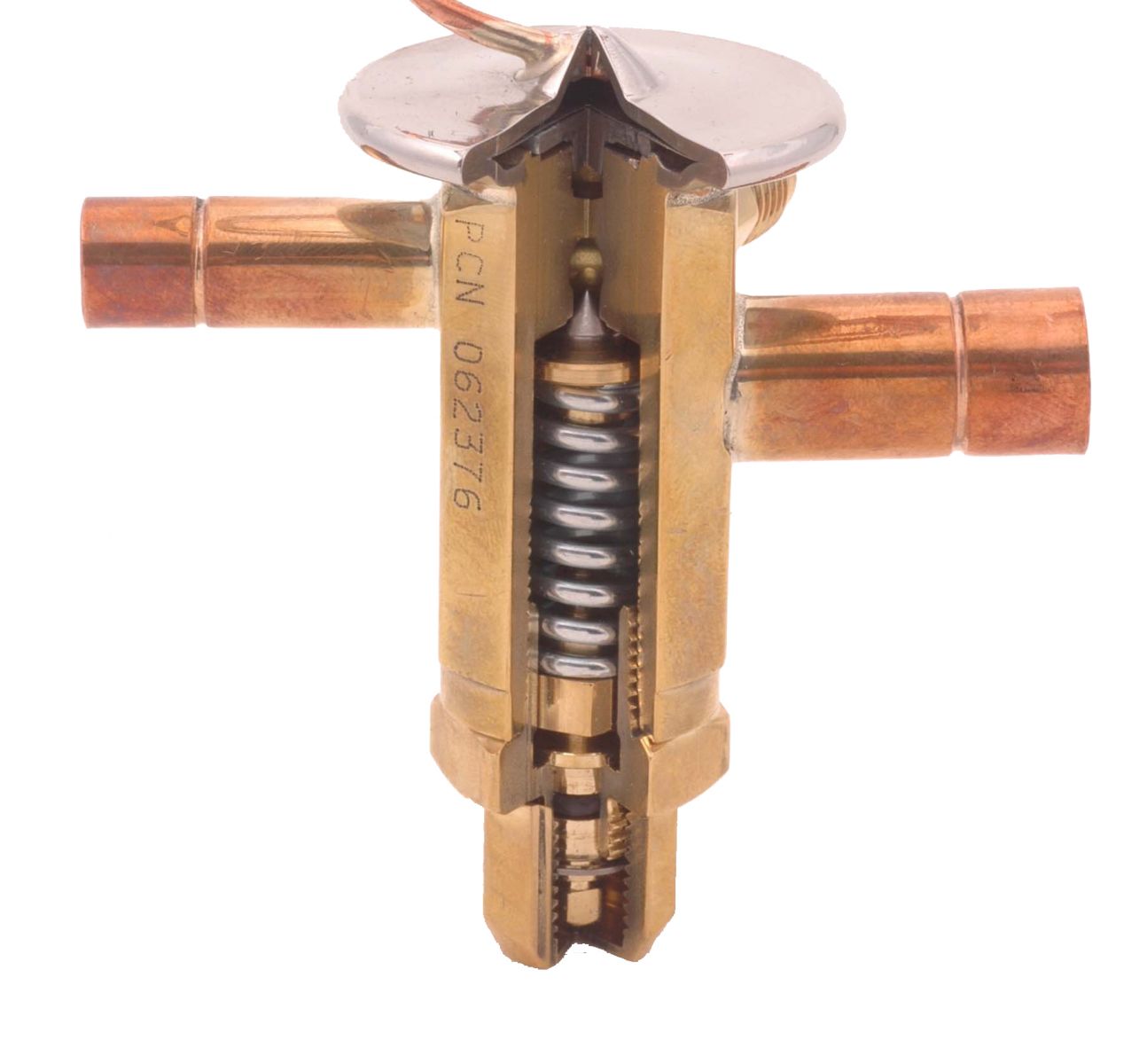

THERMAL EXPANSION VALVE A Flow control, or metering, of the refrigerant is accomplished by use of a temperature sensing bulb, filled with a similar gas as in the system. The sensing bulb mounts on the refrigerant line leaving the coil. As the temperature on the bulb increases, the refrigerant expands, pressing down to open the needle valve, allowing more refrigerant flow to the coil. As the suction line temperature decreases, so does the pressure in the bulb and therefore on the spring causing the need valve to close. COMMON EXPANSION VALVE FAILURES The most common failure with an expansion valve is loss of charge in the sensing bulb. With no refrigerant pressure to expand and open the needle valve, the expansion valve remains in the closed position, not allowing refrigerant flow into the coil, resulting in very low suction pressure or pressures in a vacuum. The most common cause of refrigerant pressure loss is a broken or worn-through sensing bulb line.

It is good maintenance practice to make sure the sensing bulb line is not touching itself or other copper lines. TESTING AN EXPANSION VALVE

This article was:

Helpful |

Not helpful

Report an issue

Article ID: 81

Last updated: 3 Feb, 2017

Revision: 16

Access:

Public

Views: 999

Comments: 0

Also read

|